Overview

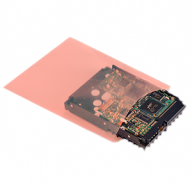

Our 7100 Clean Anti-Static Polyethylene bags are a strong, anti-static clean packaging film. They are the most cost effective cleanroom packaging solution that is made of anti-static material. 7100 Clean Anti-Static Poly are cost effective, but still provide a good level of cleanliness, anti-static protection, strength, and ease of sealing.

Continue reading “7100 Series Anti-Static Polyethylene Cleanroom Bags” »