Every manufacturing environment contains some degree of airborne particles that can negatively impact your product or manufacturing process. These contaminating particles may already be present in the environment, or they may be introduced into your manufacturing area by people or things entering into that space.

Depending on the relative sensitivity of your product or process to those contaminants, you may require a clean room for your production. But just how clean a working environment do you require? The answer to that question is quite simply: “How many contaminants do you need to eliminate?”

How Big Is Your Problem?

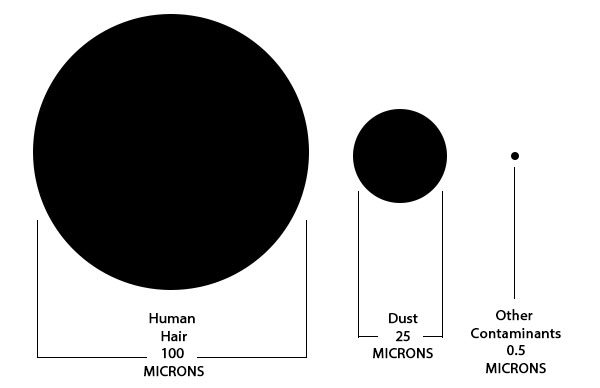

When talking contaminants, the benchmark measurement is the micron. One micron is equal to one millionth of a meter, or 39 millionths of an inch (.000039″). A human hair, for example, is about 100 microns in diameter. The human eye is capable of seeing particles down to approximately 25

microns, about the size of a speck of dust. Unless you’re involved in a super critical manufacturing situation, most clean room applications need to deal with particles about 5 microns or larger.

The class of clean room necessary to address your particular situation, will be dependent on the size and concentration of the contaminants that threaten your process. If your process is not that critical, then your clean room need not be that critical, and the numerical classification of your clean room can be significantly higher.

For example, a manufacturer of precision optical lenses for a defense

What Can Be Negatively Affected?

• Production Yields

• Product Reliability

• People

The semiconductor industry’s ability to put thousands of circuits on a miniature chip, would not exist without the elimination of sub-micron airborne particles. Other industries such as film printing, opto-electronics, powder metallurgy, laser and hard disk drive assembly, all have improved production yields by tightly controlling airborne particle contamination.

In industries such as pharmaceutical manufacturing, food processing, and medical device manufacturing, there is no margin for component failure. That is why these industries demand tight protection from contamination in their manufacturing process from start to finish.