Why is it Important to Use ESD Packaging?

To protect your product. Electrosensitive devices can be impacted by a miniscule amount of ESD. This ESD is not even visible to the naked eye but can have a detrimental impact on your production process. Electrostatic discharge can cause your product to have total failure or reduced functioning. Therefore, it is important to have proper procedures and processes in place to protect your product, which includes proper ESD packaging and clothing. The packaging you select will protect your product when it is being moved into and out of ESD-protected areas (EPA). Therefore, it is important that you select the right packaging for your specific needs.

Types of ESD Packaging

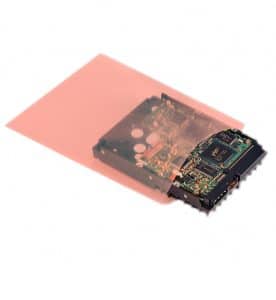

Anti-Static Bags and Film

Anti-static bags and film are manufactured with anti-static polymers. These polymers do not create static when rubbed or touched with other materials. Anti-static materials prevent the packaging from holding a charge and, therefore, will prevent the packaging from releasing a charge. This material will prevent the build-up of static charges but does not provide shielding and does not stop ESD from penetrating the bag. To prevent ESD inside the packaging, you must use shielding bags and film.

Anti-static packaging is typically transparent and can be easily seen through. As well, anti-static packaging is generally offered in various colors.

Featured Product: 7100 Series Anti-Static Bag

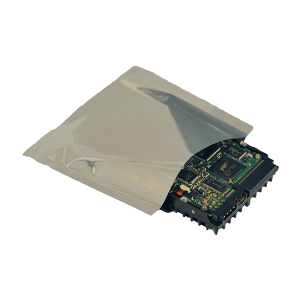

Shielding Bags and Film

Similar to anti-static bags and film, shielding bags and film are also manufactured with anti-static coatings. However, this material is also made with metalized polyester that provides shielding to the contents of the packaging. With the addition of the metalized polyester, shielding bags and films create a total Faraday cage around the product. This material will resist static discharge and protect your electro-sensitive products inside.

This material is made with layers of multiple materials to provide the characteristics desired. For shielding bags, this may include materials such as polyester, static dissipative polyethylene, aluminum, and additional static dissipative coatings.

Shielding bags and film will usually be translucent. Translucent materials can still be seen through, but the material is more smoky and not as clear as transparent packaging would be.

Featured Product: 8100 Series Static Shielding Bag

Moisture Barrier Bags and Film

This type of packaging is used when you also need a moisture or gas barrier for your product, in addition to being anti-static. Moisture barrier packaging can be used for static-sensitive products that are also sensitive to moisture or gas. This packaging is for products where MVTR (Moisture Vapor Transmission Rates) are critical. Additionally, this packaging will shield your product and protect against static discharge.

Similarly, to shielding bags, moisture barrier bags are also made up of layers of various materials. These layers include metalized polyester, polyethylene, and anti-static coatings.

Moisture Barrier bags and film can be opaque or translucent. The thicker the material gets, the more difficult it will be to see through the packaging. Some moisture barrier material will look smoky, but can still be seen through, while some will be opaque, and you will not be able to see through the packaging.

Featured Products: 3600 Series MBB, 3710 Series MBB

ESD Packaging Categories

There are three categories to consider when looking at packaging for your electro-sensitive products. The number of layers you use will depend on your product and needs.

Intimate Packaging

First Layer of Packaging: this layer physically touches and holds the product. This layer is one of the most critical layers as it will need to provide all the necessary protections for your product. When selecting intimate packaging, you will need to understand your product needs and what things your product is sensitive to. This could include static, moisture and gas.

Proximity Packaging

Secondary Layer of Packaging: this layer is generally used to hold products that are inside of intimate packaging. Proximity packaging is not designed to touch electro-sensitive products directly but can provide an additional layer of packaging and protection.

Secondary Packaging

Additional Layer of Packaging: this layer can be used if the products need additional protection beyond the first two layers. This layer will not touch the product itself and generally is not permitted inside of an EPA. This layer of packaging can be a source of ESD so it is critical to keep this material outside of ESD protected areas.

ESD Packaging at Bennett & Bennett

We are proud to offer multiple ESD packaging options to ensure your products are protected. Once you have determined your product needs you can refer to the chart down below to select the best packaging. We carry various sizes of bags and films of each product to meet your packaging needs.

As well, we would be delighted to work with you directly to determine your specific needs. You can contact us via form or call us at 937-324-1100.

Additional Resources

ESD Fundamentals | ESD Association

Why ESD packaging is so essential | Antistat (US) ESD Protection

61340-5-1: ESD protective packaging | Electrostatics.net

ESD Packaging – Packaging Requirements | Nefab Group

ESD Protective Packaging Solutions | Nefab Group

What Is ESD Packaging and Why Does Your Business Need It? | Bondline

How to Choose the Best ESD Protective Packaging for Your Company | Research Dive

ESD Packaging and Transport Archives | SCS – Static Control Solutions