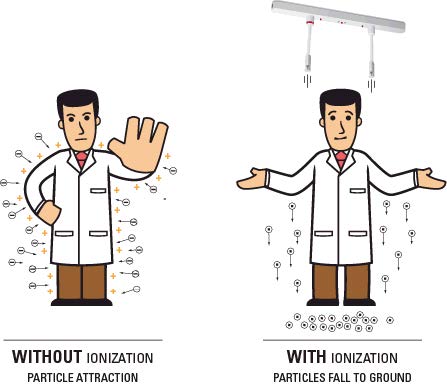

We begin by discussing the particle contamination issues in gown up rooms. Operating personnel enter gown up rooms to prepare for entry into the final clean room environment where items are processed. Without any static mitigating techniques, the operators and their clothing are statically charged causing substantial particle attraction.

Particle Count and Yield Loss Reductions:

In a study of over 100 manufacturers since 2006, it has been observed and noted that each and every facility (100%) that has done testing, has measured substantially reduced particle counts in the clean room when ionization has been implemented in the gown up room. Many facilities conducted experiments where they would turn the ionization systems on and off in the gown up room and observe the correlated rise and fall of their clean room particle counts. Almost all facilities have particle count measurement equipment, so this is an easily verifiable experiment to conduct.

Yield improvements were observed in ALL cases when only gown up room ionization was implemented. The typical reduction in yield losses due to particle contamination was 25%. That reduction was completely due to the gown up room ionization. That is a huge return on a very small investment!

Air ionization is the most effective method of eliminating static charges on non conductive materials and isolated conductors. Air ionizers generate large quantities of positive and negative ions in the surrounding atmosphere, which serve as mobile carriers of charge into the air. As ions flow through the air, they are attracted to oppositely charged particles and surfaces. Neutralization of charged surfaces can be rapidly achieved through the process.

Air ionization may be performed using electrical ionizers, which generate ions in a process known as corona discharge. Electrical ionizers generate air ions through this process by intensifying an electric field around a sharp point until it overcomes the dielectric strength of the surrounding air.

Negative corona occurs when electrons are flowing from the electrode into the surrounding air. Positive corona occurs as a result of the flow of electrons from the air molecules into the electrode.

Please note that insulative materials such as plastics, glass, rubber, ceramic, etc. will not dissipate their charge when grounded. Only bringing air ions close to their surface via ionization equipment removes the charge, which resides on the surface of the insulator.

So, How Does Ionization Help?

Ionization equipment employed in a gown up room “loosens” the particles on personnel by eliminating the attraction force and a great majority of the previously adhered particles will literally fall off of the person and their clothes due to gravity – even in the absence of any additional airflow.

Incorporating additional ionized air flows (ionizing air showers,ionizing blowers, etc.) is effective at eliminating even more of the unwanted particles from entering the clean room.

A Typical Installation of Overhead Ionizing Blowers

One or two strong ionizing blowers should be located just inside the street entrance to the gown up room, and another similar ionizing blower(s) just before the entrance to the clean room. In this way, particles are removed from personnel as they enter into the gown up room in their street clothes, and also when they are subsequently gowned and are ready to enter into the clean room. ( A pair of 3-fan overhead ionizing blowers is shown below.)

In Summary:

Ionization systems, installed in manufacturing facilities gown up rooms and product transfer areas, have proven to be critical components in reducing particle counts in the associated clean room production and assembly areas. These reduced particle counts translate into substantial reductions in yield losses and rework.