Cleanroom packaging is a critical component of an effective cleanroom. Cleanliness must be maintained until the product reaches the end user, otherwise, the benefits of clean manufacturing are lost. It is crucial to consider all aspects of the production process and have a clear understanding of your needs. Both cleanroom gowning and cleanroom packaging are essential to creating an effective cleanroom. The cleanroom packaging selected is essentially a mobile cleanroom, so choosing the proper packaging is vital.

There are numerous characteristics to consider when selecting cleanroom packaging. Is the product sensitive to particles, moisture, or electrostatic discharge? Is it all of the above or a combination? Do you need to be able to see the product inside the packaging?

Producing a “clean” product does not mean the same thing to every manufacturer. Each product is unique, and it is necessary to understand the specific requirements for your cleanroom packaging.

Once you know your packaging requirements, it is important to know what materials can be used in a cleanroom. There are numerous materials that can be used for cleanroom packaging and each one has its strengths and disadvantages. We will be discussing six different materials that can be used for clean packaging:

Packaging Materials

Clean Room Packaging Terms

There are various terms that are used when referring to cleanroom packaging. Some of these terms include the following:

ESD: Acronym for Electrostatic Discharge. The discharge of static energy that emits heat, light, and sound.

Hygroscopic: The ability of a material to absorb moisture, hygroscopic materials absorb moisture readily from the environment

Outgassing: The transfer of gaseous material onto a product inside the bag.

Sloughing: Material shed onto a product inside the bag when the film is flexed.

Cleanroom Packaging Materials

Polyethylene

Polyethylene is used in cleanrooms all around the world for every application imaginable. The primary reason for its universal usage is low cost.

There are several forms of polyethylene including Low Density (LDPE), Medium Density (MDPE), High Density (HDPE), and Anti-Static Low Density (SDLDPE). Chemical and physically pure polyethylene film is created by using a specialized clean resin that contains no regrind, slip, or anti-block agent.

Polyethylene has a low melting point and is easily heat-sealed, making it a common choice as the inner layer of most laminated structures.

Clean Polyethylene tubing, sheeting and bags are available in various widths, colors, and thicknesses from 2 mils to 8 mils. All cleanroom poly bags are available with or without anti-static properties.

Featured Products: 7000 Series, 7100 Anti Static Series

Nylon

Nylon is a blown film extrusion. The advantages of Nylon film are toughness, vacuum sealability, and a suitable gas barrier. However, nylon is hygroscopic which makes it a poor moisture barrier. Nylon also has a high melting point, which can make heat-sealing more difficult.

Clean Nylon sheeting, tubing, and bags are available in various widths.

Featured Product: 7200 Series

Biaxially Oriented Nylon/Polyethylene

Biaxially Oriented Nylon/Polyethylene is a visually clear, moisture and gas barrier material that is puncture resistant and vacuum sealable. This material does not stretch due to the alignment of the nylon and polyethylene.

These films typically have been manufactured with a small amount of slip agent and generally are not available in anti-static versions.

Biaxially Oriented Nylon/Polyethylene cleanroom bags and sheeting are available in various sizes.

Featured Product: BB450 Series

Metalized Polyester/Anti-Static Polyethylene Laminate

Metalized Polyester / Anti-Static Polyethylene Laminate is manufactured with a thin layer of aluminum that is sputtered onto the surface of polyester and then laminated to anti-static polyethylene. The resulting material can be used to make a static shielding bag that forms a Faraday cage around ESD-sensitive electronics and is heat-sealable.

Metalized Polyester/Anti-Static Polyethylene Laminate in 3 mil thickness provides a small amount of moisture and gas barrier protection while protecting the contents from ESD damage. The material is translucent allowing the contents of the packaging, including barcodes, to be read through the bag.

Featured Product: 8100 Series

Metalized Polyester/Anti-Static Polyethylene Laminate can also be purchased in 7.1 mils thickness which creates a better moisture and gas barrier, while still protecting the contents from ESD damage. However, the product will no longer be able to be seen clearly through the packaging.

Featured Product: 3710 Series (coming soon)

Selecting your Cleanroom Packaging Supplies

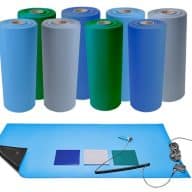

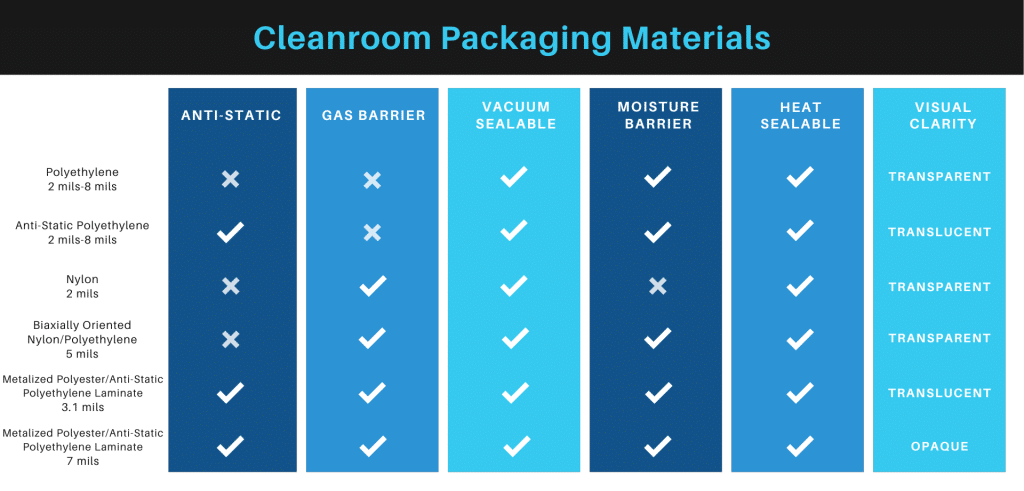

Now that we have gone through some of the most common cleanroom materials, you can determine which product is most suited for your cleanroom. All the materials are heat and vacuum-sealable and provide some level of visual clarity. However, your needs regarding anti-static, gas barrier, and moisture barrier properties may help determine the best packaging.

The chart below gives an overview of the various products that are offered at Bennett & Bennett for clean packaging. For more precise specifications, view the specs guide provided for each of our products on their product information pages.