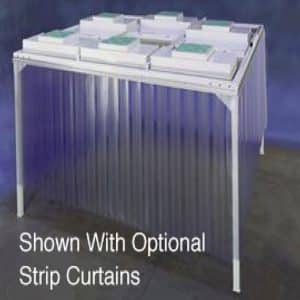

A softwall clean room is exactly as the name implies, it has soft flexible walls rather than hard rigid walls. It is typically smaller in size than a traditional hard wall clean room. While fixed wall clean rooms may be the order of the day for large, more permanent manufacturing and assembly operations, softwall clean rooms are a cost-effective alternative solution when size, flexibility, and possible portability are viable issues.

Softwall clean rooms are sometimes described as “prefabricated clean rooms”, “portable clean rooms”, “clean room tent-like enclosures”, etc. Whatever you call them, they all share the same properties: relatively inexpensive, easy to install and take down, and easy to expand if necessary.

Ideal for a leased building situation

Not able to add a necessary room since you do not own the building? A softwall clean room from Bennett & Bennett, Inc. is a perfect solution. And it is a piece of capital equipment that you own and can take with you if you move to a new location.

Create a clean room within a clean room

If you need tighter classifications for certain parts of your manufacturing or assembly process, simply add a smaller room to accomplish that need. It is not necessary to bring a large hard-walled clean room to higher standards that are only required for one or a few operations.

Can be easily relocated

Softwall cleanrooms can be moved within an existing facility, or to a new location altogether. These rooms can be easily installed in any location to provide a clean air environment wherever you may need it.

Softwall clean rooms from Bennett & Bennett, Inc. are available in many standard sizes, and we offer custom-engineered softwall clean rooms for demanding and unique applications. Self-contained rooms are offered in ISO Class 5 through 9, or US Federal Standard 209 Class 100 through 100,000. Standard rooms are equipped with Fan Filter Units for HEPA filtration, lighting, a 4´ strip door, and solid curtain wall panels.